Baby Boomers, Millennials, And The Future Of The Water Industry

By Kevin Westerling,

@KevinOnWater

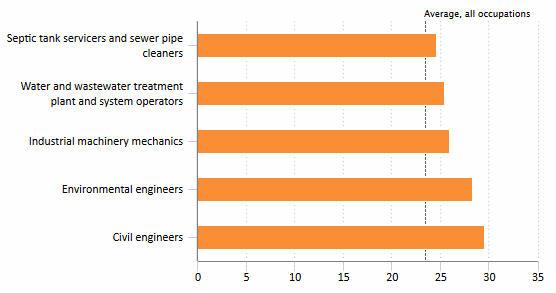

If you've ever attended an event or conference with a large number of water and wastewater professionals, you likely noticed a lot of white hair in the room. It's an observation supported by data, as the U.S. Bureau of Labor Statistics (BLS) predicts the rate of retirement to be higher than average throughout the industry, with water/wastewater treatment plant operators leaving at a rate above 25 percent and environmental/civil engineers' exodus nearing 30 percent through 2024. These job openings from attrition are "in addition to opportunities arising from growth," BLS notes.

Selected water-related occupations with above-average replacement rates in all industries, projected 2014-24 (Source: U.S. Bureau of Labor Statistics)

Filling their shoes will be millennials (also known as Generation Y), born between 1980 and the end of 1994, as well as Generation Z (so dubbed for now), born from 1995 on. Having grown up with the internet, this influx owns a certain set of traits and advantages not so prevalent in the baby boomers they're displacing, but they don't have any of the institutional knowledge of the 'white hairs' in the room.

What is the effect of this labor transition as it relates to technology, knowledge transfer, and the future of the industry? While at the 2017 AWWA Annual Conference and Exposition (ACE17), Water Online surveyed our Water Talk podcast guests — technology providers who serve the utility and engineering community — on their perceptions of and preparations for a baby boomer-to-millennial changeover. Here are some of their thoughts [paraphrased].

Pat Whalen, President and CEO of LuminUltra Technologies, stressed the need to digitally catalog and leverage institutional knowledge.

We have to gather the knowledge of those retiring baby boomers and put it into cloud-based platforms or training packages — whatever it may be so that the next generation doesn’t make the same mistakes that others may have made in the past. We need to enable these platforms to interpret that data and knowledge and make it available 24/7, 365.

Christine Scorza, Senior Director of Software & Services at Aclara, a provider of advanced metering infrastructure (AMI), highlighted the changing face of decision-makers and technology demand.

Buyers of AMI today are looking for a very different set of criteria than what they were five or six years ago. They’re looking for mobile-friendly solutions; they want to arm their field technicians with devices like tablets to provide a single point of view for their customers [ratepayers]. It’s really driving a lot of the design decisions that we’re making, and the way we’re doing this is by engaging with our customers [municipalities] through customer advisory boards. It’s very different than the legacy software that Aclara used to make; we’re expanding our portfolio to continue to meet the market where it is going.

Daryl Weatherup and Russ Swerdfeger of Evoqua Water Technologies talked of the talents that the next generation offers, perfectly suited to industry trends.

When we look at the generation just coming out of college, they’re a lot more tech-savvy than the folks getting ready to move onto the next phase of their lives, as they exit the workforce.

A lot of our newer technologies have a heavy technology component — internet and computer technology — associated with it. The higher-end control systems feature sophisticated human-machine interaction. That trend actually lends itself well to membrane filtration, because the control systems are so much more sophisticated than your traditional mixed media filters.

For us, it’s about getting this new generation familiar with our technology and the principles of the product itself, but then not to encumber them; let them use their own innate creativity to continue to drive, innovate, and advance technologies themselves.

Alon Vaisman, Head of Sensors and Automation at Malvern Instruments, noted that “gut feel” control of operations is basically nontransferable, but new tools provide alternatives befitting the latest crop of talent.

It’s not easy to transfer years of experience, especially when that experience is based on essentially a gut feel or a know-how that is not necessarily recordable, quantifiable, and directly transferable. This is where the application of scientific tools and solid technology comes into play, because it’s easy to train a new person to be able to control to a certain parameter rather than being able to train them to control to a certain gut feel or to a certain level of experience.

The younger generation is much more comfortable with technology and computer-based systems. People like seeing solid numbers, numbers that they can trust.

The process really requires a transformation from the art of water plant control to a science of water plant control, and this is where we hope to play our small part.

AdEdge Water Technologies' President, Rich Cavagnaro, along with Director of Business & Project Development, Ronit Erlitzki, suggested that the time is exactly right for fresh, computer-savvy talent.

Young people have a skill level and ability to multitask that we, even in our generation, don't fully appreciate.

One of the things that AdEdge has been doing with remote monitoring is a ‘911 Box’, which we send out to our sites so that we can log on and see the programming information of our systems. With young operators, there is no fear with this technology that we’re bringing in into the marketplace. With operators that are retiring, we have a much more difficult time getting them to use some of the new things.

So from our standpoint, it’s exciting to bring in younger people because they're more used to [utilizing tools for] transferring information — and exciting, I think, for young folks getting into the water treatment industry.

Cara Baldwin, Vertical Marketing Manager, U.S. Drinking Water, with Hach Company, focused on opportunities created by our smart-phone culture, with new recruits leading the charge.

This new generation has such a comfort level with hand-held devices. We’ve all got iPhones and other phones in our hands at all times; we’re very mindful of that and we do a tremendous amount of customer research to understand those pain points and opportunities, so that we can offer information and data that provides insights that customers can act upon.

Our R&D team is developing data solutions that are incorporating mobile technology at a greater degree and, frankly, pretty much all of our products now are ‘smart’ products — they’re able to talk to each other — with increased opportunities for connectivity.

We’re driving in that direction and very much mindful of the change that’s coming in the industry.

Ian MacLeod, VP of Marketing for Master Meter, flipped the script on the knowledge-transfer assumption, noting that older people can also learn from the young.

The exchange of information is two-way. I would like to submit to you that some of the younger people coming into our industry are bringing with them a wealth of expertise and understanding of technology and how it can be applied in our space.

This younger set is doing so much to teach us and educate us, and then we’re also able to exchange information with them based on our years of experience. It’s really an exciting two-way exchange of ideas and best practices.

While it is two-way learning, filling the roles and replacing the experience of operators is still real challenge — one that was addressed by GF Piping Systems’ Brian LaBelle, Director of Business Development, Water Treatment & Energy.

The fact is, by sheer numbers, as the baby boomers retire there are not always enough operators. So the concern is not just inexperience coming in to replace the experienced, it’s not having enough actual bodies to do the work that we traditionally relied on in the past.

What we’ve done is put together GF Technology seminars that are not really product focused — they’re more technology-solutions-oriented, so we become instructors for the operators. We have an accredited program where operators can get CEUs, continuing education units, to help renew their operator's licenses.

These education services are one thing that we’re doing directly as a manufacturer to support our products, but also [the industry] in general, by teaching on types of products and the applications that those products fill in the markets that we serve.

David Barrasse, sales manager at Brentwood Industries, expanded on education and recruitment, focusing on millennials and even post-millennials.

We’re actually trying to get them before they’re engineers.

I can’t tell you how many times our HR department has pulled in some environmental science class from high school or college into our office. Brentwood supports the industry in terms of bringing those younger people in and trying to educate them — because, let’s face it, our industry has done a pretty poor job over the last 10 or 15 years of bringing younger folks into this industry.

We do everything. We have internships with five or six colleges, many of which have interns who come in and work for the summer, and end up getting a job.

The last word from our vendor contingent comes from Greg Livelli, Senior VP and Head of Product Portfolio Management at ABB, who summarized what is and what’s to come.

You have a legacy workforce — this is how they do things, and they’re not going to change much.

You have a new workforce that’s coming, looking for ease of use and ease of access — they don’t want manuals and they don’t want datasheets; they look it up on their phones or their iPads.

It’s an interesting dynamic to manage both sides, but eventually it will switch to one side. And that’s when people will start to be able to use the smarts that come out of the instruments.

Perspectives vary, of course, and I appreciate all of the views shared by our Water Talk interview subjects.

Personally, I think that you can teach an old dog new tricks — specifically, that veteran operators can learn to be comfortable with new technology. I also believe that the younger set can learn a “feel” for operations, even if they grew up with iPhones in their hands. It’s a matter of motivation, for both individuals and organizations, to adapt in the inevitable times of change — and especially important in our industry, for which the change is imminent.